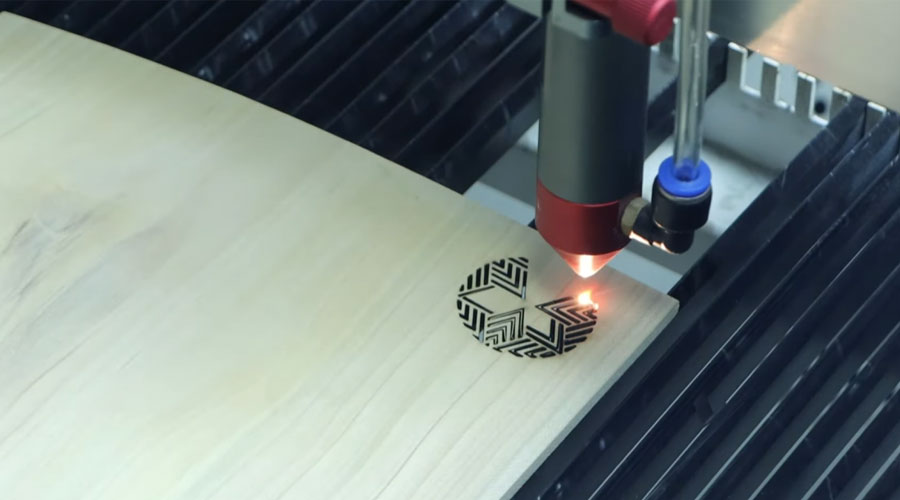

[vc_row][vc_column][vc_column_text css=””]Hi, the crafters, DIY enthusiasts, and small business owners! Let’s talk about something that’s revolutionizing woodworking: laser cutting machines. Specifically, why a laser cutter designed for wood and medium-density fiberboard (MDF) might be just what you need. Whether you’re making custom furniture, intricate decor, or prototyping products, this tool is a powerhouse.

Before you start buying, let’s break down the uses, reasons, and ways to buy one so you can make an informed and affordable choice. I’ll throw in some real-world examples and compare the top models.

1. Why Laser Cutting Machines Dominate Wood & MDF Projects

Wood and medium-density fiberboard (MDF) are versatile and adaptable materials that traditional cutting tools such as saws or CNC milling machines have limitations, cannot handle extreme details, waste materials and time-consuming setup.

Here’s why they’re winning:

- Precision: Cut intricate designs (think lace-like patterns or tiny joints) without splintering.

- Speed: A laser works 3–5x faster than manual tools.

- Flexibility: Switch between cutting, engraving, and even 3D texturing.

- Cost-Effective: Less material waste = more profit.

A small furniture biz in Texas slashed production time by 60% after switching to a CO2 Laser Engraving Cutting Machine. Their ornate chair designs? Now a bestseller.[/vc_column_text][cz_gap height=”30px”][vc_row_inner][vc_column_inner width=”1/3″][cz_image id=”cz_52625″ image=”3345″]Laser Cutting Machine for Wood MDF[/cz_image][/vc_column_inner][vc_column_inner width=”1/3″][cz_image id=”cz_76015″ image=”3344″]Laser Cutting Machine for Wood MDF Pattern[/cz_image][/vc_column_inner][vc_column_inner width=”1/3″][cz_image id=”cz_61031″ image=”3346″]Laser Cutting Machine for Wood MDF Desk[/cz_image][/vc_column_inner][/vc_row_inner][cz_gap height=”30px”][vc_column_text css=””]

2. CO2 vs. Fiber Lasers: Which is Better for Wood?

Not all lasers are equal! Check out this quick comparison:

| Feature | CO2 Laser | Fiber Laser |

|---|---|---|

| Best For | Wood, MDF, acrylic, fabric | Metal, plastic, some alloys |

| Cutting Speed (Wood) | 15–25 mm/s | 10–15 mm/s |

| Engraving Detail | High | Medium |

| Maintenance | Moderate | Low |

| Price Range | 15,000 | 50,000+ |

Verdict: CO2 lasers are best for wood/MDF processing, they are cheaper, faster, and produce better detail. Fiber lasers are best for metal processing.[/vc_column_text][cz_gap height=”30px”][vc_video link=”https://www.youtube.com/watch?v=GJcQMSr_xOQ” css=”” title=”Laser Cutting Machine for Wood | MDF Laser Cutting Machine”][cz_gap height=”30px”][vc_column_text css=””]

3. Special Guide for Woodworking BOGONG Laser Machine

Here’s a cheat sheet of BOGONG’s top wood-friendly models:

CO2 Laser Engraving Cutting Machine

- Power: 40W–150W

- Materials: Wood, MDF, leather, acrylic

- Key Perks: Budget-friendly, ideal for small shops.

- Link: CO2 Laser Engraving Cutting Machine

5050 Fiber Laser Cutting Machine

- Power: 500W–3000W

- Materials: Thin wood, plywood, and light metal engraving.

- Key Perks: Dual-use flexibility.

- Link: 5050 Fiber Laser Cutting Machine

Smallest 3020 Fiber Laser Cutter

- Power: 300W

- Materials: MDF, bamboo, paper

- Key Perks: Compact, perfect for home studios.

- Link: 3020 Fiber Laser Cutter

4. How to Choose YOUR Perfect Machine

Follow this checklist (adapted from BOGONG’s guide):

- Material Thickness: For MDF >6mm, pick a 100W+ CO2 laser.

- Workspace Size: Got a tiny garage? Go compact like the 3020 model.

- Budget: Start small. Upgrade later.

- Software Compatibility: Ensure it works with your design tools (Adobe, AutoCAD, etc.).

Pro Tip: Use BOGONG’s free consultation form to get personalized advice.

5. Safety First: Keeping Your Workspace Secure

Using laser cutting machines involves inherent risks, particularly fire hazards and fumes. Always follow these safety guidelines:

Ensure Good Ventilation: Protect your health by ensuring harmful fumes, especially from MDF, are properly vented out.

Wear Protective Gear: Invest in quality safety glasses and appropriate gear.

Fire Safety: Always keep a fire extinguisher nearby.

Our machines at Bogong Laser incorporate advanced safety features, helping you stay protected without compromising on productivity.

6. Wondering how a laser cutter can boost your business or hobby?

Examples:

Wooden Jewelry Maker: One of our clients switched from manual cutting to our Smallest Fiber Laser Cutting Machine and increased their production speed by over 200%, with more precise and intricate designs.

Furniture Manufacturer: A furniture company invested in our Laser Plate & Tube Combo Fiber Laser Cutting Machine, cutting MDF panels more efficiently, reducing waste by nearly 30%, and significantly boosting their profit margins.

Why Bogong Laser?

A comprehensive range from hobbyist machines to powerful industrial solutions. Visit our laser cutting machines page and explore how Bogong Laser can transform your woodworking or MDF crafting experience.

[contact-form-7 id=”a8c851c” title=”Contact form 1″][/vc_column_text][/vc_column][/vc_row]