Laser Cutting Machine for Metal

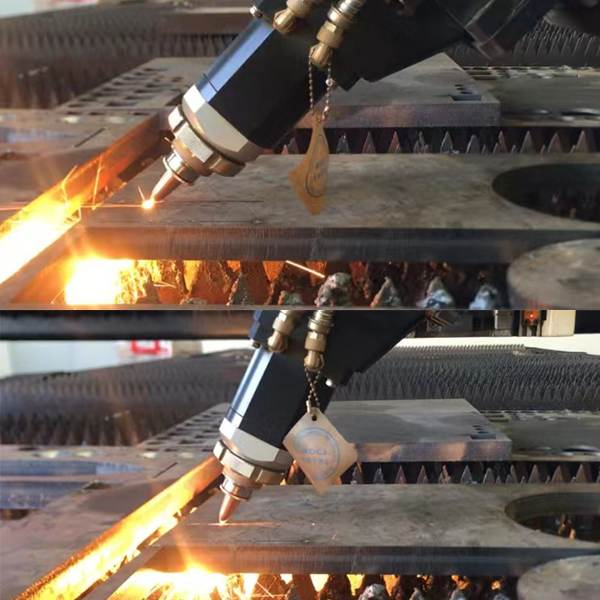

Laser cutting machines use a focused laser beam to cut metals such as stainless steel, carbon steel, aluminum, copper and titanium. The process is fast, precise and has a narrow kerf, enabling detailed and complex designs that are difficult to achieve with traditional mechanical methods. Laser cutting is widely used in sheet metal processing, metal parts manufacturing and prototyping.

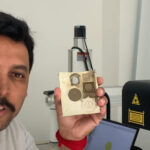

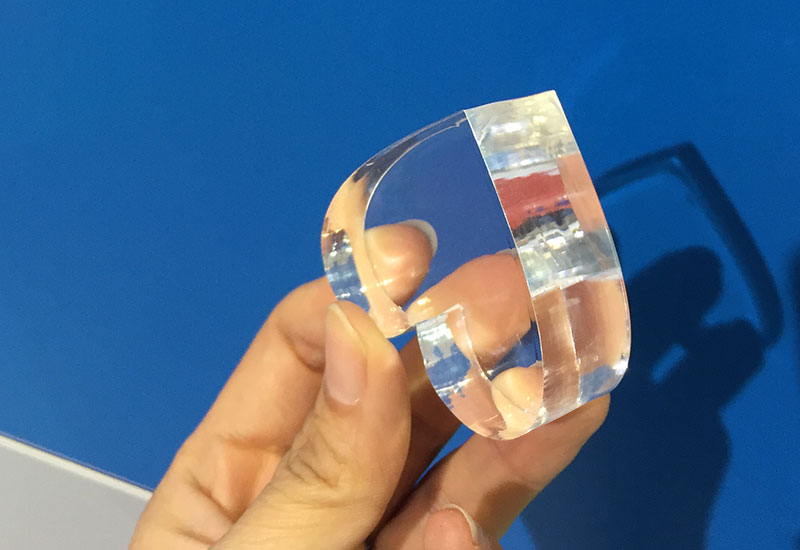

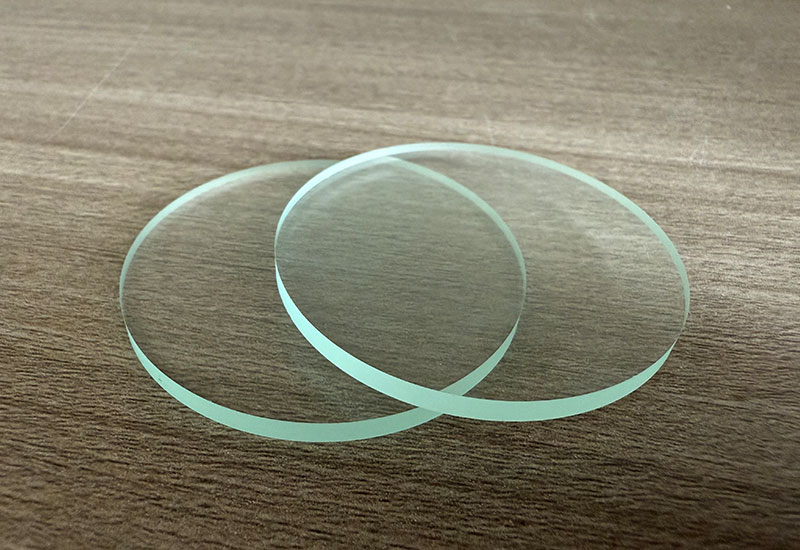

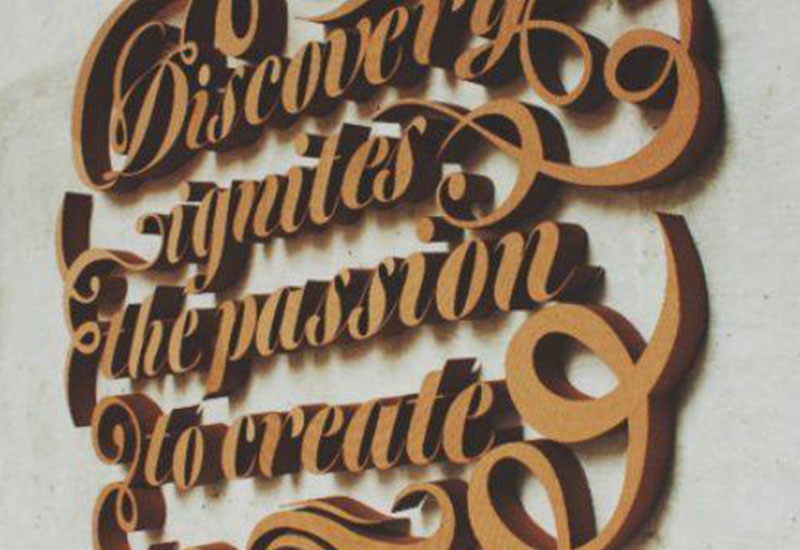

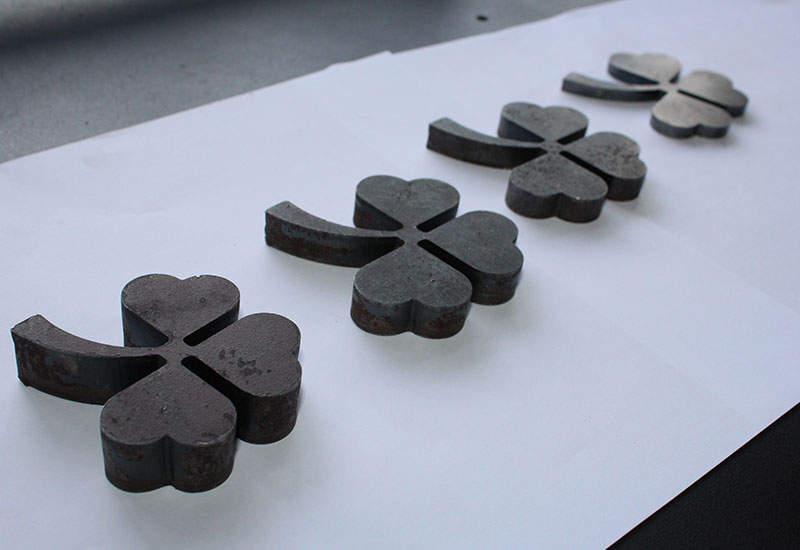

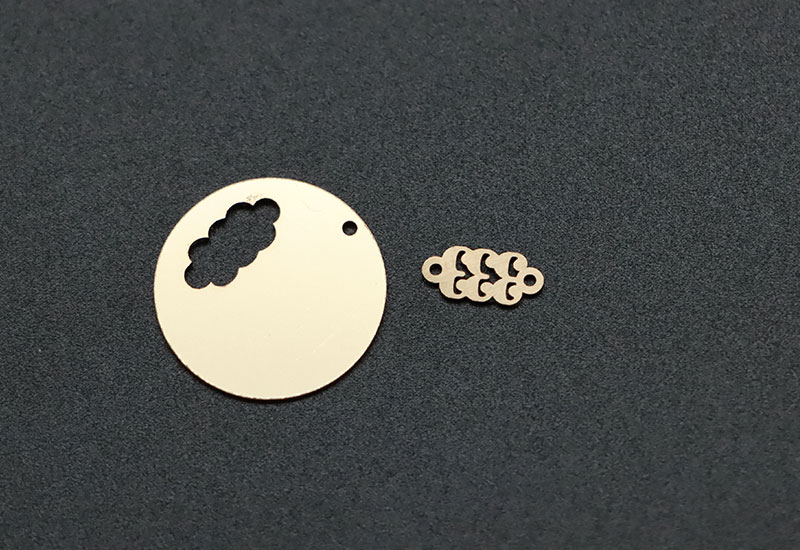

Laser Cutting Machine for Metal Results Showcase Images

Laser cutting of metals produces clean edges with minimal burrs and distortion. Demonstrating fine cuts, smooth edge finishes, and the process’s versatility on different metals.

Visual examples include:

- Stainless steel sheet laser-cut components

- Aluminum parts with complex geometric patterns

- Copper and brass decorative pieces

Laser Cutting Machine for Metal Results Showcase (1)

Laser Cutting Machine for Metal Results Showcase (2)

Laser Cutting Machine for Metal Results Showcase (3)

Laser Cutting Machine for Metal Results Showcase (4)

Laser Cutting Machine for Metal Results Showcase (5)

Laser Cutting Machine for Metal Results Showcase (6)

Laser Cutting Machine for Metal Results Showcase (7)

Laser Cutting Machine for Metal Results Showcase (8)

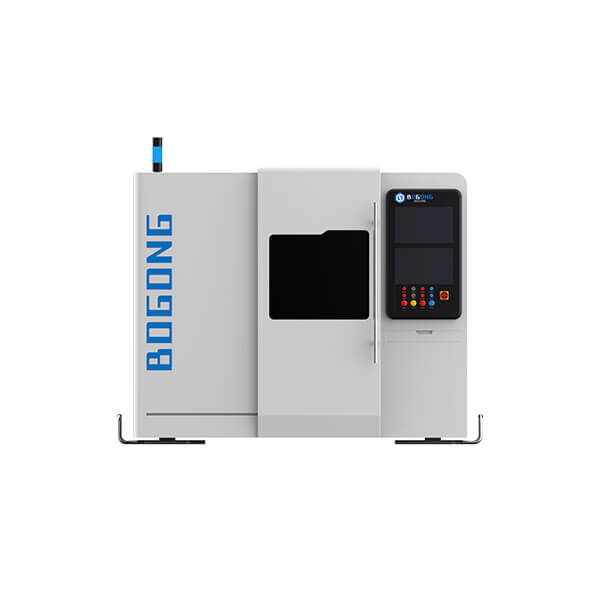

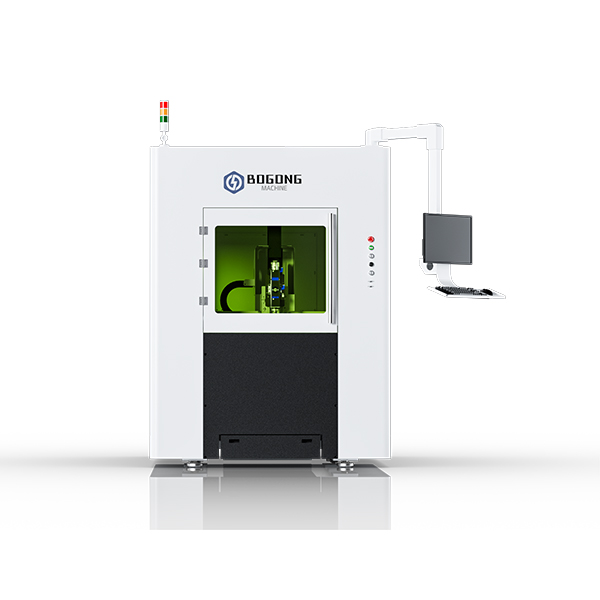

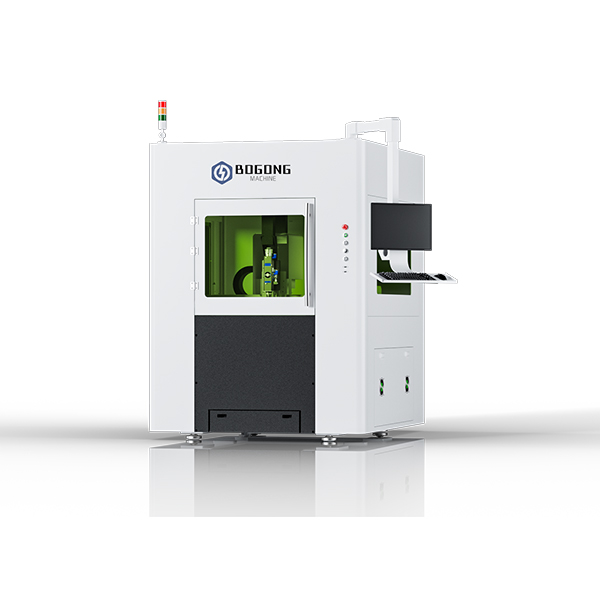

Laser Cutting Machine Product Recommendation

To meet different production needs, we recommend laser cutting machines optimized for metal processing.

Laser Cutting Machine for Application

Discover other laser cutting and marking applications relevant to metal fabrication.

Frequently Asked Questions (FAQ)

Most metals including stainless steel, carbon steel, aluminum, copper, brass, and titanium can be effectively laser cut.

Depending on power, laser cutters can cut metal sheets up to several centimeters thick.

Laser cutting minimizes heat-affected zones and distortion compared to traditional cutting, especially with proper settings.

Regular cleaning of optics and periodic calibration keep the machine performing optimally.

Contact Us to Help You Choose the Laser Cutting Machine that Suits You:

If you need help selecting the right laser cutting machine or have any questions, please contact us. Fill out the form below or reach us by phone or email for expert assistance tailored to your metal cutting needs.

BOGONG LASER® Blog – Laser Cutting Machine Application and Industry Information

Learn more about laser cutting metal and related topics with our expert blog posts

CO2 Laser Cutting Machine for Foam Tool Inserts

2025-11-14

Laser Metal Cutting Machine for Construction Formwork

2025-11-12