Laser Cutting Machine for Sheet Metal

Laser cutting has become a go-to solution for fabricating sheet metal components with outstanding precision and speed. This contactless process reduces material distortion and production time, making it ideal for industries such as automotive manufacturing, aerospace, electronics, and construction. The versatility of laser cutting also allows designers and engineers to push creative boundaries with intricate patterns and detailed designs that traditional cutting methods struggle to achieve.

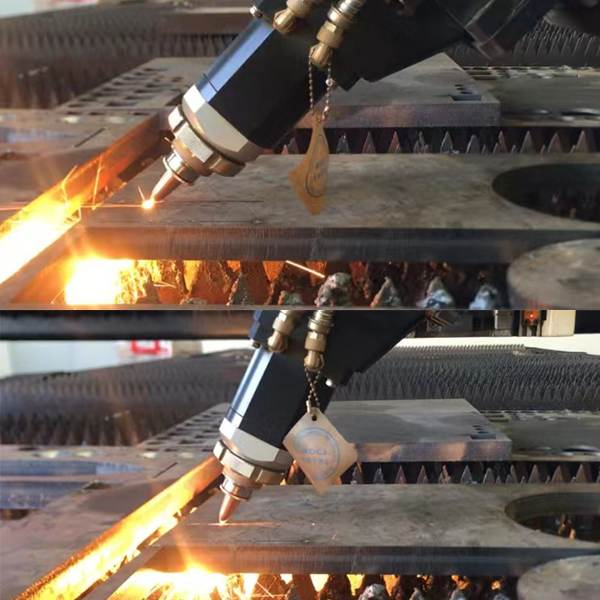

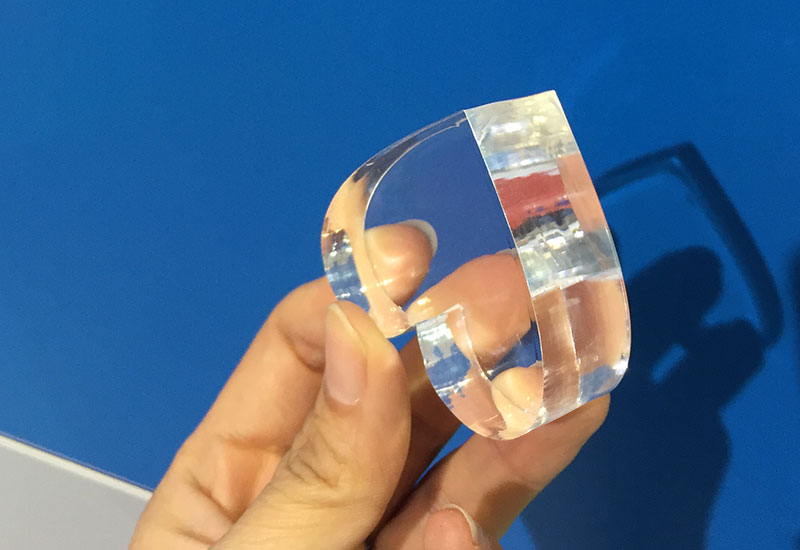

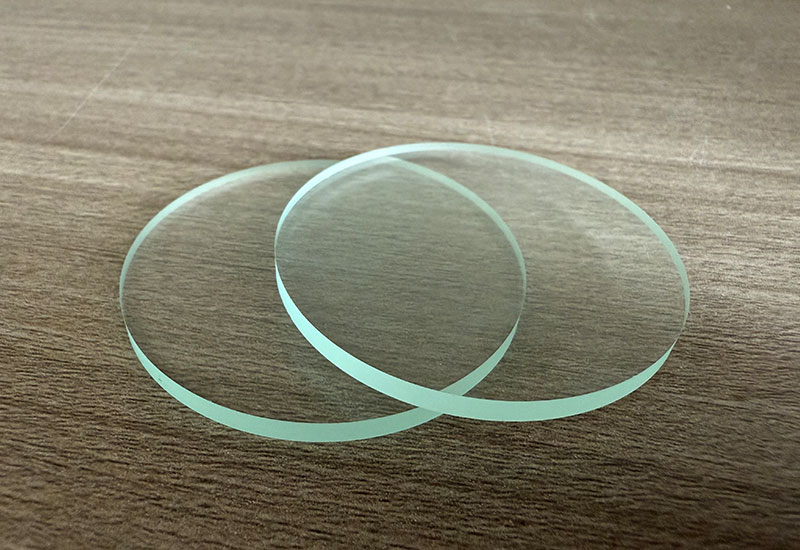

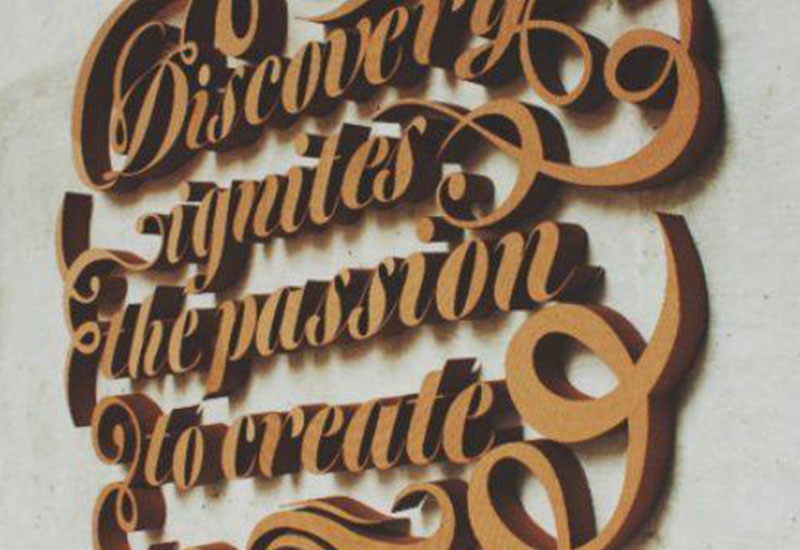

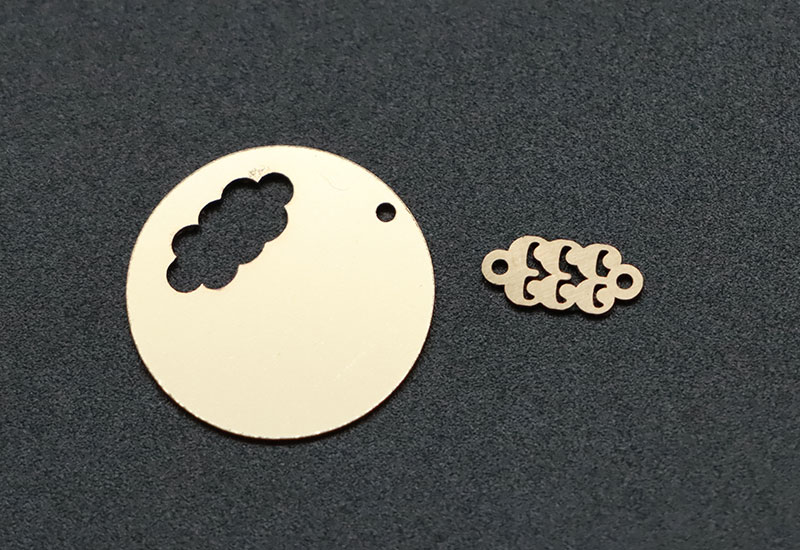

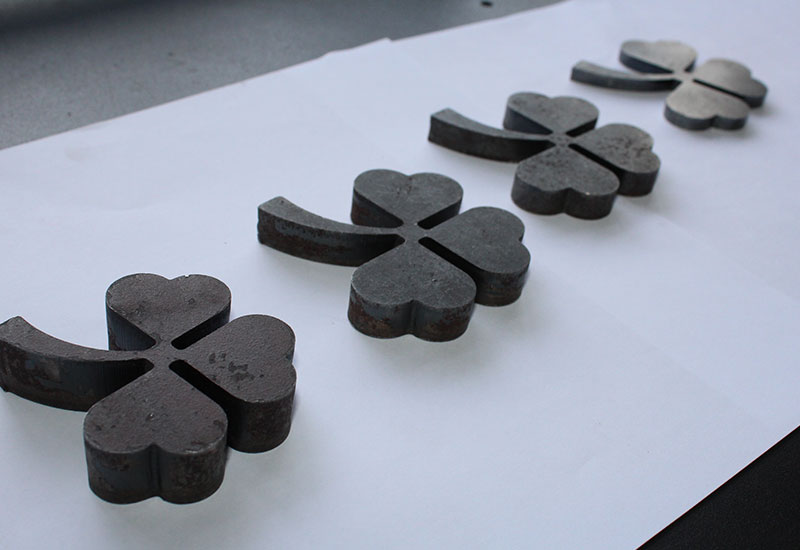

Laser Cutting Machine for Sheet Metal Results Showcase Images

Laser cutting sheet metal produces clean edges with minimal burrs or warping. This gallery showcases finished components illustrating intricate cutouts, smooth finishes, and versatility across different metal types and thicknesses.

Visual examples include:

- Stainless steel sheet metal components

- Aluminum panels with complex geometric patterns

- Copper and brass decorative sheet metal pieces

Laser Cutting Machine for Sheet Metal Results Showcase (1)

Laser Cutting Machine for Sheet Metal Results Showcase (2)

Laser Cutting Machine for Sheet Metal Results Showcase (3)

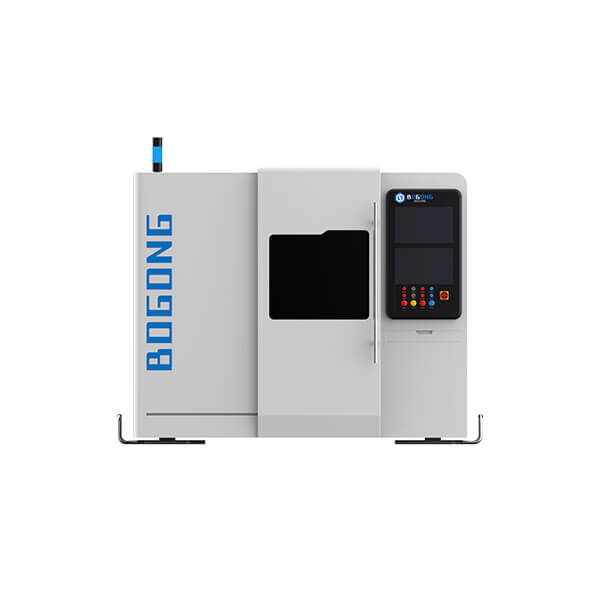

Laser Cutting Machine for Sheet Metal Results Showcase (4)

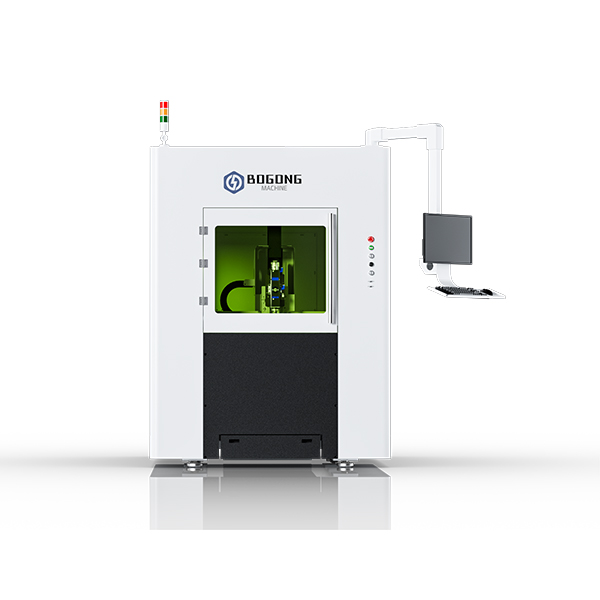

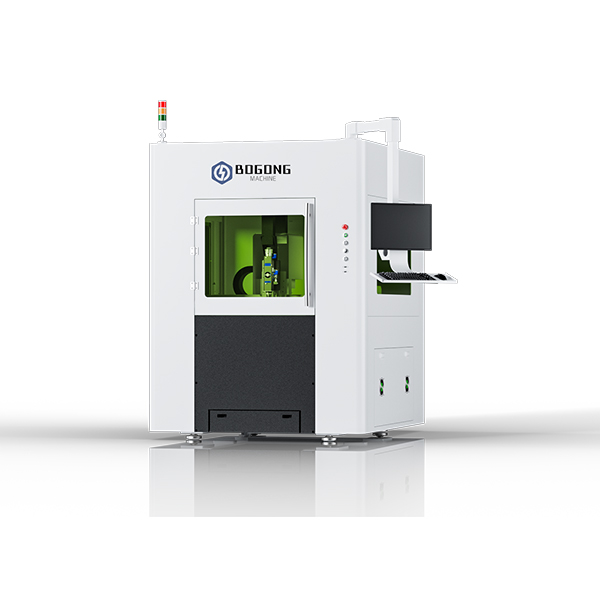

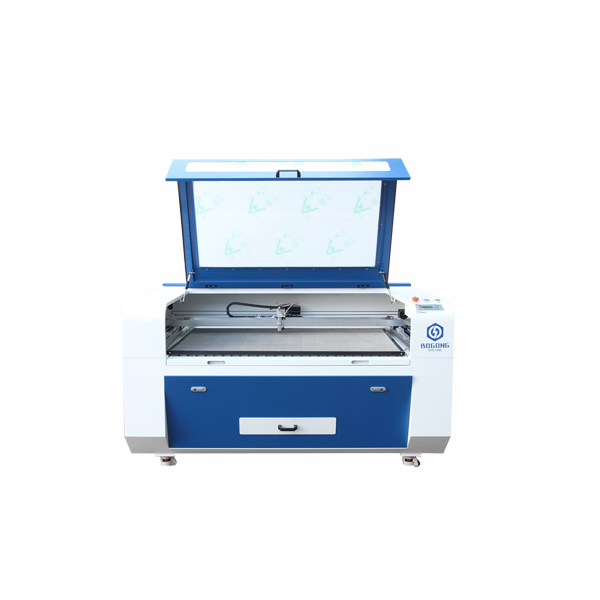

Laser Cutting Machine Product Recommendation

To meet diverse sheet metal cutting needs, we recommend laser cutting machines optimized for different production scales.

Laser Cutting Machine for Application

Learn what other applications laser cutting machines can be used for. Help you find the right product for your industry.

Frequently Asked Questions (FAQ)

Common materials include stainless steel, carbon steel, aluminum, copper, and brass.

Depending on laser power, sheet metals up to several centimeters thick can be cut.

Laser cutting minimizes heat-affected zones and distortion compared to traditional methods when optimized.

Routine cleaning of optics and periodic calibration maintain optimal performance.

Contact Us to Help You Choose the Laser Cutting Machine that Suits You:

If you need help choosing the right sheet metal laser cutting machine or to discuss your project requirements, please contact us and we will provide professional and customized assistance based on your sheet metal cutting needs.

BOGONG LASER® Blog – Laser Cutting Machine Application and Industry Information

Learn more about topics related to laser cutting machines

CO2 Laser Cutting Machine for Foam Tool Inserts

2025-11-14

Laser Metal Cutting Machine for Construction Formwork

2025-11-12