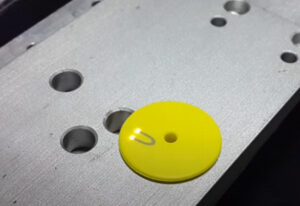

[vc_row][vc_column][vc_column_text css=””]A Plastic Laser Marking Machine Manufacturer produces and markets laser devices particularly designed for marking plastic products. These equipments use concentrated laser light beams to produce irreversible marks on plastic surface areas, offering benefits like high speed, accuracy, and sturdiness.[/vc_column_text][cz_image id=”cz_58548″ image=”5846″][/cz_image][cz_gap height=”20px”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Matching Plastic Materials with Laser Types

When you picking a laser, you need to match your plastic’s molecular to a laser’s wavelength.

-

Fiber lasers rock on ABS, PE and PP. They cut through tough polymers with good beam quality.

-

CO₂ lasers handle acrylics and PC in thicker gauges. They ride on thermal melt to carve deep marks.

-

UV lasers nail down micro marks on sensitive polymers. They shatter molecular bonds so heat build-up stays chill.

You’ve probably seen cheap machines scorch edges or cause melt-backs. That’s ‘thermal lensing’ messing with your beam spot. At BOGONG Lazer, we dial in fiber, CO₂ or UV units so you don’t wrestle with hot spots.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

[/vc_column_text][vc_video link=”https://youtu.be/67x9mS49GoA” css=””][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Non-Contact Marking

Traditional engraving tools wear down fast. They nick your parts, leave burrs and demand constant tool swaps. Laser marking stays airborne, which means:

-

You get permanent marks that resist abrasion and chemicals.

-

You avoid downtime caused by contact wear and maintenance pauses.

-

You cut back on scrap and rework.

One factory we work with is switching to UV marking for their plastic pipes. The marks are sharp and crisp, and the edges stay cool. UV marking works great on both thick and thin-walled pipes.

[/vc_column_text][cz_image id=”cz_99435″ image=”5854″][/cz_image][cz_gap height=”20px”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Precision, Efficiency & Cooling

-

Spot size control. Tiny mark, big detail. No beam scatter, no halo.

-

High throughput. Jump-mark speeds that keep pace with conveyor.

-

Cooling scheme. Fiber lasers like air-cool setups. CO₂ and UV lasers usually need water chillers to stay stable.

Chasing spikes in laser power lead to“beam jitter”—it influence mark quality. At BOGONG Laser, we factory-tune chill cycles and beam alignment so your parts look consistent. You’ll dodge ghost-image and tail-mark issues.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Laser Comparison Table

| Lazer Tipi | Suitable Plastic Scenarios | Cooling Method | Temel Avantajlar | Common Issues |

|---|---|---|---|---|

| Fiber Lazer | ABS, PE, PP in signs & stickers | Air-cool | Fast cycling, long diode life, low upkeep | Limited on transparent plastics |

| CO₂ Lazer | Acrylics, PC in panels & sheets | Water-cool | Deep melt marks, cost-friendly setup | Larger heat-affected zone |

| UV Lazer | High-precision plastics & coatings | Water-cool | Cold-mark tech, micro-etch, minimal discoloration | Higher initial cost, slower pace |

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Common Pain Points & Industry Jargon

-

Fume extraction. Smoke can blur optics. You need inline filters or louvers that pull vapors away.

-

Back-reflection. Some plastics throw light back. You risk diode damage. Anti-reflection modules fix that.

-

Beam drift. Thermal expansion in the head can nudge the beam. Active beam-path monitoring keeps your spots tight.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Scenarios & Use Cases

A signage shop that marks serial codes on polycarbonate badges. They tried a CO₂ unit, but they got uneven depth and scorch marks on edges. We helped them swap in a UV head, added a pulse-control kit, and it fixed their “heat-fell” issues.

Another factory needed to print micro QR codes on plastic equipment. They tried a BOGONG marking machine and later commented, “We had no idea plastics could be marked so cleanly.”

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Choosing Your BOGONG Laser Solution

-

Bizim göz atın 30W Fiber Lazer İşaretleme Makinesi for chip-tight marks on plastics.

-

The classic CO2 Lazer İşaretleme Makinesi rules in thicker polycarbonate jobs.

Don’t miss the UV Lazer İşaretleme Makinesi if you need cold-mark finesse.

-

Or go all-in with the Hepsi Bir Arada Lazer Markalama Makinesi—it handles plastics and metals in one shot.

BOGONG Laser builds modular heads, so you swap diodes on the fly. You’ll cut changeover time, shrink footprint and boost your bottom line.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””]

Toparlıyoruz

Choosing a plastic laser marking machine isn’t difficult. Match your resin to the right beam, lock down cooling, and tackle fume and beam drift head-on. BOGONG Laser brings global B2B creds, top-tier certs and real-world know-how right to your shop floor.

Feel free to fill out the contact form on BOGONG Laser to get the convo started.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text css=””][contact-form-7 id=”a8c851c” title=”Contact form 1″][/vc_column_text][/vc_column][/vc_row]